Quality

|

|

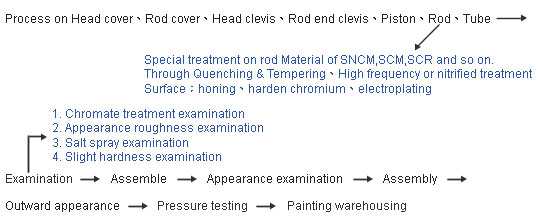

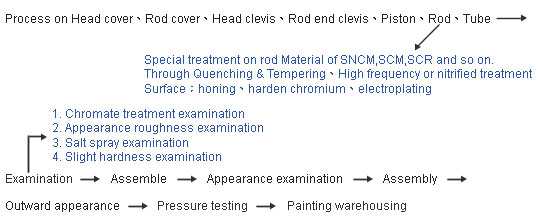

| Tube quality Control → honing process → inside diameter inspection → antirust treatment → turn in and store up | |

|

|

|

|

|

![]() Quality Control.:

Quality Control.:

|

|

|

||

|

|

|

||

|

|

|||

|

|

|

||

|

|

| Tube quality Control → honing process → inside diameter inspection → antirust treatment → turn in and store up | |

|

|

|

|

|

![]() Quality Control.:

Quality Control.:

|

|

|

||

|

|

|

||

|

|

|||

|

|

|

||

|

|

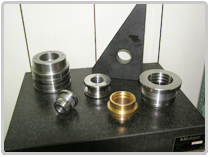

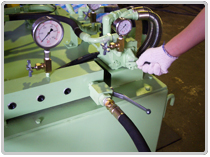

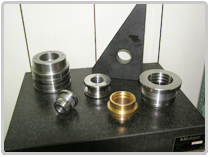

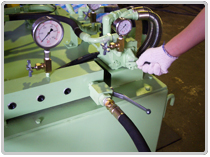

| We pursue the most perfect design by using Auto CAD & Solid Works and try to satisfy all the necessary consideration. Also we must strictly control the thickness of steel material to conform customers’ specification. There are many Staffs in charge of all specific position to make sure the production smooth with perfect quality. Explanation as below: 1. Development and Design 2. Review and correction for drawings 3. Issue and control for drawings 4. Material quality inspection and machining formation 5. Arrived material inspection and quality control 6. Quality control for assembling process 7. Good quality consistently for all finished cars 8. Document control and management for completed cars 9. Tracking and after service for sold cars. |

|

|